Filtration unit FJ – underpressure

Filtration unit FJ – underpressure

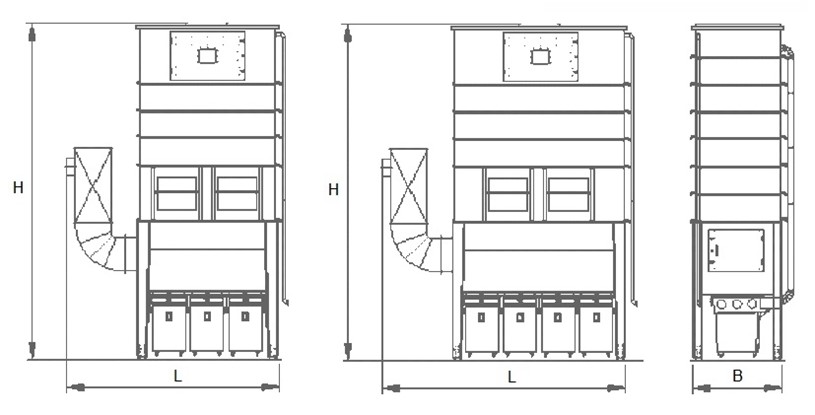

back to FJ filtration unitFiltration units are used for separation of waste material from woodworking technology. Steel galvanized structure is equipped by filter hoses from high quality polyester material. Separated waste material falls down into steel containers. Modular design allows multiply capacity. Each module has own vibration motor for filter regeneration. According to ventilator and filter unit arrangement we can divide filtration units to:

Filtration unit – underpressure

At underpressure arrangement is filter unit ordered prior to ventilator. Ventilator is working in clean air. Vibration filter regeneration is done by stopped ventilator. In addition we can install filter regeneration by pressed air blow. That regeneration can be done during ventilator work and significantly increase filtration efficiency and filter hose live.

Basic equipment of FJ module

- 60 or 78 filtration hoses with diameter of 160 mm and length of 1500, 2000, 2500, and 3000 mm

- vibration motor for filter regeneration

- optionally in addition system of pressure air blow

- inlet chamber for air speed decrease and herewith increase of filtration efficiency

- steel containers for waste collecting

- inspection door

- dry fire extinguishing system

- safety flap for explosion release

Filtration units FJ can be installed outside the building and filtered air can be returned back into working area.

Advantages

- in comparison to overpressure arrangement is underpressurre system more suitable for extraction of materials, those cause higher filter load and higher risk of explosion – e.g. fine dust developed by sanding

- filter regeneration by pressure air blow increase filtration exfficiency and filter hoses live

- ventilator ordering after filtration unit allows to choose ventilator with higher efficiency impeller and herewith safe installed power of ventilator

Ventilator is not a part of filter unit and type is chosen according to extraction requirements.

Technical specification

Dimensions and technical parameters

| type | filtrating area

m2 |

containers volume

l |

width

mm B |

length

mm L |

height

mm H |

Inlet

mm |

capacity

m3/hod |

| FJ-P 45-3BO | 45 | 3 x 150 | 1250 | 2750 | 4537 | 300 | 4500 |

| FJ-P 60-3BO | 60 | 3 x 150 | 1250 | 2750 | 4937 | 300 | 6000 |

| FJ-P 75-3BO | 75 | 3 x 150 | 1250 | 2750 | 5337 | 350 | 7500 |

| FJ-P 90-3BO | 90 | 3 x 150 | 1250 | 2750 | 5737 | 350 | 9000 |

| FJ-P 78-4BO | 78 | 4 x 150 | 1254 | 3344 | 4937 | 350 | 7800 |

| FJ-P 98-4BO | 98 | 4 x 150 | 1254 | 3344 | 5337 | 400 | 10000 |

| FJ-P 117-4BO | 117 | 4 x 150 | 1254 | 3344 | 5737 | 400 | 11700 |

| FJ-P 120-6BO | 120 | 6 x 150 | 1250 | 4750 | 4937 | * | 12000 |

| FJ-P 150-6BO | 150 | 6 x 150 | 1250 | 4750 | 5337 | * | 15000 |

| FJ-P 180-6BO | 180 | 6 x 150 | 1250 | 4750 | 5737 | * | 18000 |

| FJ-P 160-8BO | 160 | 8 x 150 | 1254 | 5938 | 4937 | * | 16000 |

| FJ-P 200-8BO | 200 | 8 x 150 | 1254 | 5938 | 5337 | * | 20000 |

| FJ-P 240-8BO | 240 | 8 x 150 | 1254 | 5938 | 5737 | * | 24000 |

*inlet diameter has to be stated individually